Rockfall Netting

Terra Aqua High-Resistance Rockfall Netting is ideally suited for difficult solutions to rock face problems, since the double-twist, hexagonal-woven mesh does not unravel when wires abrade. Fractured stones are trapped and confined against the slope should isolated wires fatigue from prolonged stress. Additionally, this double-twisted hexagonal type of netting has the high mechanical resistance required to prevent the danger of sudden rock shock loads and dissipate rock fall energy created from loose fractured rock.

In times past, the danger represented by falling rocks and by rocky debris from slopes overhanging the road side was not given the requisite consideration. Land was not at the premium it is today since traffic volume and patterns have changed drastically.

In recent years, however, the widening of existing roads and the opening of new roads and highways must accommodate modern transportation demands. For this reason we are faced with the problems of protecting the road side from rock slides in a safe and efficient manner.

The High-Resistance Rock-Shield Netting with the double-twist mesh has solved this problem, and is now being used extensively across the United States.

The main advantages over other types of mesh are the features of flexibility, non-raveling design, superior corrosion resistance and unique mechanical characteristics.

Applications and Placing Schemes:

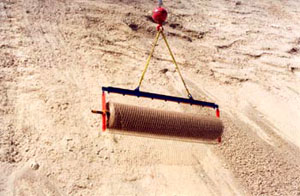

The placing of rock fall netting can vary according to the slope, its geophysical nature, the sizes of the loose boulders and the possibility of anchoring the top and base of the netting. As soil and slopes can have different characteristics each time, we are presenting only general criteria for carrying out protection with high-resistance, hexagonal double-twisted mesh netting.

Anchoring the Top:

On top, the netting must be firmly anchored to the soil and possibly folded on itself for one foot to one and one-half feet. A general method of placing cannot be suggested, as different systems should be adopted according to the nature and condition of the soil. The following are the most common methods:

- Cracked hard rock not subject to deterioration: Simple and/or double expansion bolds of 1/2-inch diameter placed on three-foot to six-foot centers.

- Compact rocks subject to deterioration: Drill a series of holes at least one and one-half feet deep on six-foot centers into the rock. Steel reinforcing bars (#4 or #5) will be inserted, hooked and then anchored by filling the holes with grout, mortar or special resins.

- Compact soils: At the same distance, steel reinforcing bars (#6), two and one-half feet long, shall be driven into the soil and fabricated with hooks to which the netting shall be tied.

- Organic and soft soils: In this case, the use of anchoring bars (0.5 inch to 0.6 inch diameter, at five foot to six and one-half feet centers) buried in concrete is recommended. The netting shall be tied to the bars by means of a continuous steel rope.

In many cases, eye bolts are substituted for reinforcing steel. A steel cable (3/8 to 1/2) is then laid out in a designed grid system and tied to the mesh and the eye bolt or attached to the cable grid with approved interlocking fasteners.

Anchoring the Face:

If necessary, before laying the netting, the slope must be reclaimed, blasting to remove all loose rocks and boulders. The netting sheets (15 feet wide) shall be carefully tied together using lacing wire or interlocking fasteners at the sheet overlap.

Where overlapping occurs, usually at the vertical splice of adjoining sheets, a minimum one-foot overlap is recommended. Horizontal splices may be required as job site conditions dictate. In these situations, refer to the design engineers' splicing detail.

When it is necessary to prevent loose rocks from cascading down the slope, a suitable sheet of gabion mesh shall be anchored to the rock face of either drilled and grouted anchors or to a designed grid system (10 to 15 square yards). The type of anchorage to be used will vary according to the slope characteristics (please refer to Item 1).

Treatment of the Toe:

The following choices can be effective: (1) In order to carry out the removal of debris more easily, the netting is simply left loose at its base for approximately one (1) foot; (2) In order to contain the debris rolling down the slope and piling up at the toe of the protection, the netting is anchored at its base. This anchorage, carried out according to the above-mentioned methods, must allow for the removal of accumulated debris from time to time.

Specifications:

- Roll Size: 15 feet x 300 feet

- Mesh Opening: 3 x 4 nominal (8 x 10 cm)

- Wire Size: .118 (3.0mm)

- Wire spec: QQW-461H, STM-A641, available in galvanized and galvanized with a sheath of PVC.

In severely corrosive environments or in seaside locations, the use of heavily zinc-coated and PVC-coated wire mesh is recommended. The PVC coating, .0216 thick, is applied to the wire core by the extrusion method. This characteristic does not alter the remarkable flexibility of the product, which has been extensively time tested on gabions and Reno mattresses.